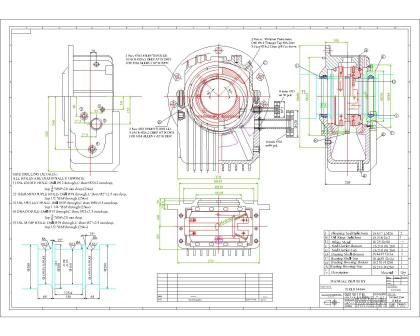

Assembly drawing showing shaft details, tolerances & all mating details

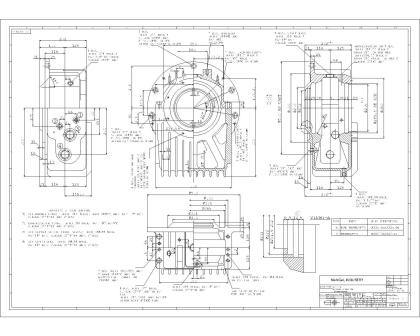

Sample housing machining drawing showing all details.

Hydrodynamic radial journal bearings

Calculation in accordance with Niemann

Calculation of power loss, oil throughput, oil warming, minimum lubricating gap size in accordance with G.Niemann. Calculation for pressure lubrication bearings (circulating oil lubrication) with test for operating safety.

Calculation according to ISO 7902

Calculation provides good, detailed method for calculating stationary, hydrodynamic plain radial bearings that are to run at low and average speed.

Hydrodynamic axial journal bearings

Calculation in accordance with DIN 31653

Complete calculation of axial bearing accordance with DIN 31653, part 1 to 3 for pressureless lubrication & pressure lubrication bearings. All operating data as stipulated in DIN 31653, such as operating temperatures, minimum lubrication gap width, power loss, oil throughput, etc are calculated.

Calculation in accordance with DIN 31654

Complete calculation of axial bearings in accordance with DIN 31654, part 1 to 3 for pressureless lubrication and pressure lubrication bearings. The type of lubricating feed (lubricating holes, lubricating grooves, lubricating pockets) is taken into account. All operating data stipulated in DIN 31654, such as operating temperature, minimum lubrication gap width, power loss, oil throughput , etc is calculated. Sample calculation output is attached for your reference.

| ANALYSIS OF HYDRODYNAMIC JOURNAL BEARINGS | ||

| Analysis according DIN 31652 | ||

| Closed bearing | ||

| Heat transfer by lubricant | ||

| Oil inlet pressure (bar) | [Pen] | 2.00 |

| Speed (1/min) | [n] | 1500.00 |

| Type of oil | Oil : ISO-VG 68 | |

| Kinem. Viscosity Oil at 40 oC (mm2/S) | [nu40] | 68.00 |

| Kinem. Viscosity Oil at 100 oC (mm2/S) | [nu100] | 8.80 |

| Directional Constants | [m] | 3.571 |

| Specific density at 15 oC (kg/dm3) | [ro] | 0.885 |

| Bearing diameter (mm) | [D] | 225.00 |

| Bearing Width (mm) | [B] | 120.00 |

| Radial force (N) | [F] | 46000.00 |

| bearing Clearance at 20 oC (mm) | [S] | 0.3400 |

| Material Shaft | C45 (1) | |

| Youngs modulus (N/mm2) | [E] | 206000.00 |

| Poisson's ratio | [ny] | 0.300 |

| Coefficient of expansion (1/oC) | [alfa] | 11.50 10exp-6 |

| Material hub | C45 (1) | |

| Youngs modulus (N/mm2) | [E] | 206000.00 |

| Poisson's ratio | [nY] | 0.300 |

| Coefficient of expansion (1/oC) | [alfa] | 11.50 10exp-6 |

| Lubrication arrangement (according DIN 31652, Part 2) : | ||

| Two lubrication holes, at 90 degree to the direction of load | ||

| Lubrication hole diameter (mm) | [dH] | 12.00 |

| Mean Surface pressure (N/mm2) | [P] | 1.70 |

| Circumferential speed (m/s) | [U] | 17.67 |

| Oil inlet temperature (oC) | [t1] | 40.00 |

| Oil exit temperature (oC) | [t2] | 59.06 |

CNC machining facility for housings shell & seals.

All finish machine operations of bearings, housings & seal is done on CNC machines only. Process for the same is

VMC Machine, Doosan Make

CNC VTL Machine, Jyoti Make

| SR.NO | DESCRIPTION | MAKE | SPECIFICATIONS |

| 1 | CNC Vertical Turning Lathe | Jyoti 750 B |

|

| 2 | Vertical machining Centre | Doosan DNM 650/50 II |

|

| 3 | CNC Horizontal Boring Machine | Kuraki, Japan |

|

| 4 | Vertical Turning Lathe | Sedin |

|

| 5 | Turret Lathe | Kirloskar |

|

| 6 | Centre Lathe | Rajkot |

|

| 7 | Centrifugal Casting Machine | Own |

|

| 8 | Vertical Milling Machine | Graffenstaden |

|

| 9 | Radial Drill Machine | Rajkot | Drilling Capacity - 40 mm |

| 10 | Melting Furnace | Konark | 150 kg Capacity, Gas fired |

| 11 | Over head Crane | Weight lifter | 3 Ton capacity |