General

Technical Information

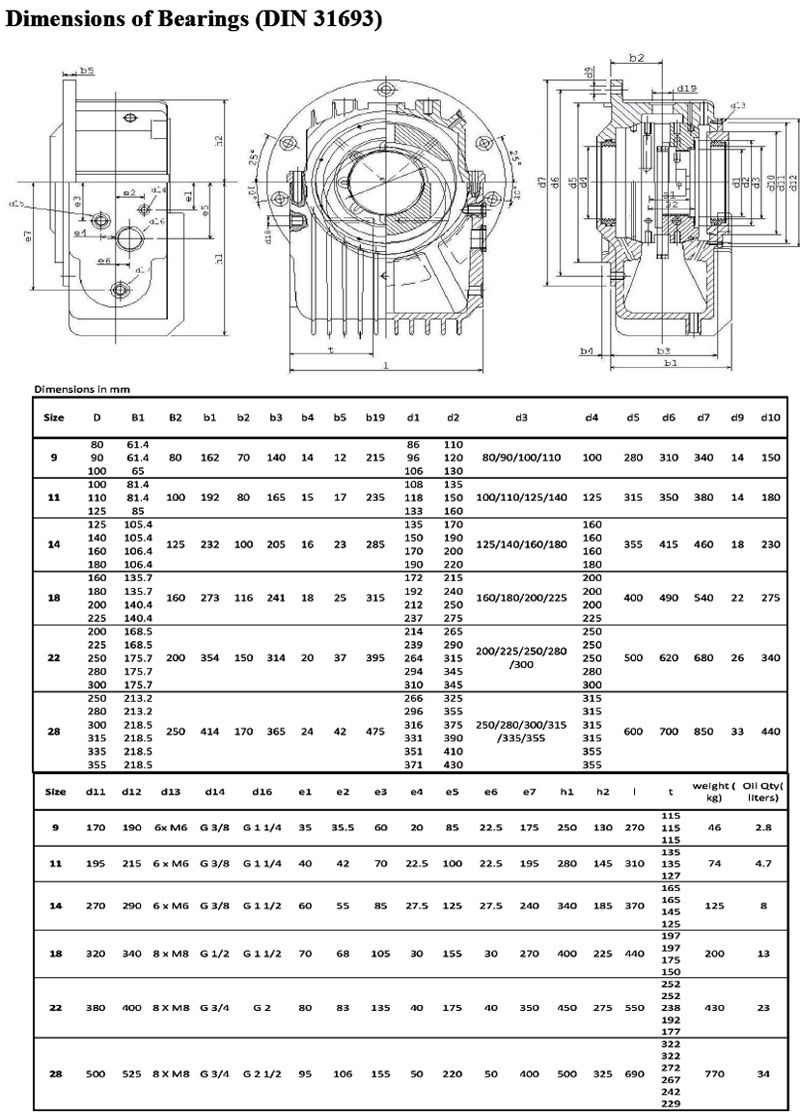

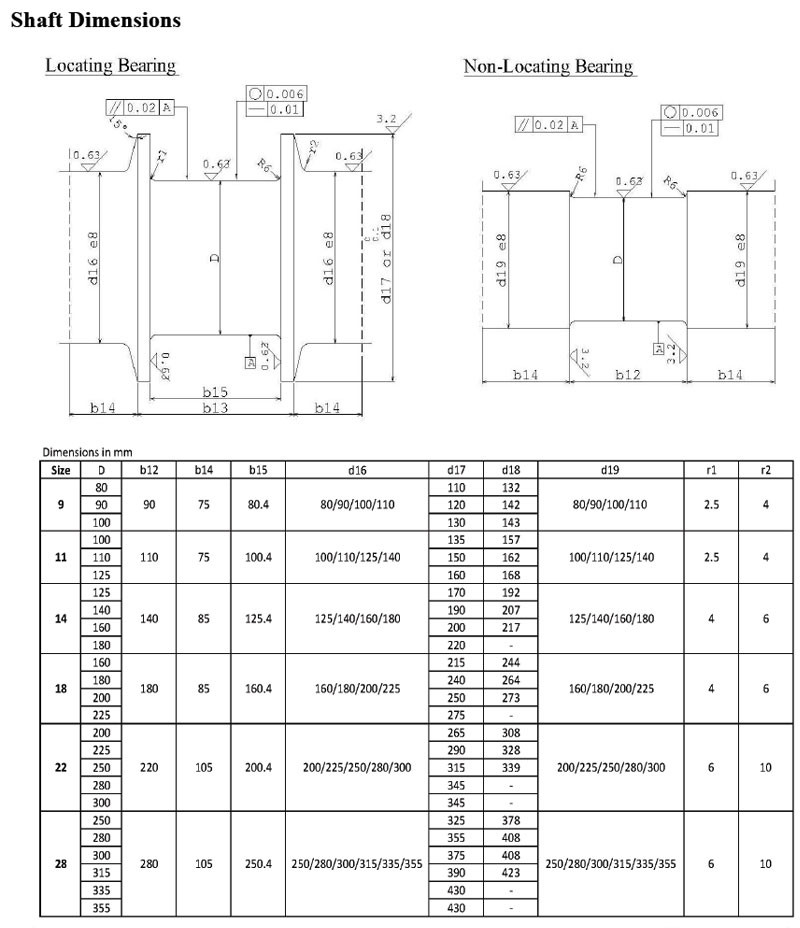

The Side Flange Bearing type MF is a variant of the M modular Bearing system. End-flange Bearings (type MF to DIN 31693 specifications are mainly applied on electrical machines, turbines, fans and blowers and marine applications. The Bearing is a stand alone bearing requiring no additional support.

Elements of the M Modular system can readily be combined or exchanged. For example, it is easy to change a bearing shell with plain axial thrust shoulders for one with taper-land thrust faces.

The M module Bearings are designed for ease of assembly by positioning the screws, pins etc. in such a way that assembly failures can be eliminated.

Housing

The finned bearing housings are made of high quality cast iron. The spherical bearing shell support is designed for even load distribution to the bottom half of the bearing housing is suitable for high loads.

On request, the housing can be made of nodular cast iron or cast steel. The cast steel housings are supplied without fins.

Tapped holes for temperature and oil level monitoring and oil inlet/outlet are available on both sides of the Bearing housing. If required, provision for oil cooler and vibration metering instruments can be provided by simple additional work on finished housings.

Bearing Shell

The Bearing shell comprises of a steel body, lined with Tin based white Metal. It is supported by the spherical seat of the Bearing Housing. Depending on applicational requirements, different types of Bearing Shells are used, for example :

Q – Bearing Shell Without metal shoulders.(non-locating bearing only)

B – Bearing Shell With plain white metal lined thrust Shoulders with Oil Pockets.

K – Bearing Shell With White Metal lined thrust shoulders With taper-land faces.

The MF Bearing with Guide Bush and loose oil ring can be used for marine application.

Lubrication

Up to 20 m/s peripheral speed, a Lubrication of Bearing shell is normally achieved through application of loose oil ring. If required, bearing can be equipped with internal oil cooler or arranged for external oil supply with external oil cooling. When external circulating oil system is connected, the oil ring provides emergency oil supply in the event of failure of the external oil supply system for the length of shout-down period.:

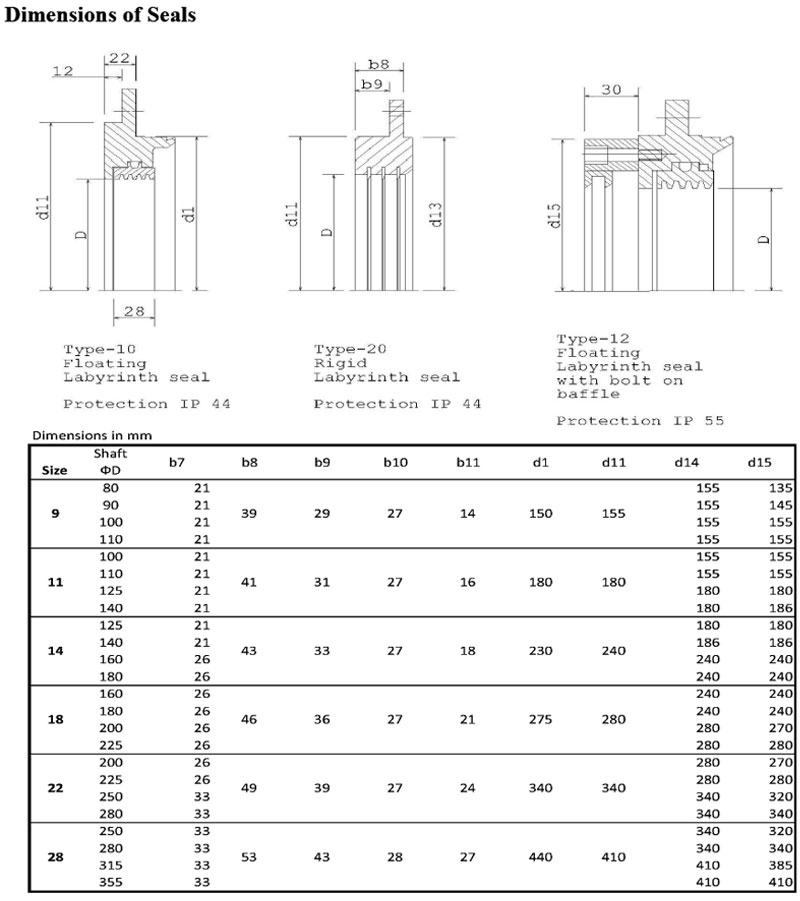

Seals

For standard application, MF Bearings are supplied with floating labyrinth seals. The seals are made from high temperature resistant material and achieve protection grade IP-44. Other seals available with the M modular range are :

Rigid Seal (IP 44) for high oil throughput.

Floating labyrinth seal with additional bolt-on baffle (IP-55)

Rigid seal with additional bolt-on baffle (IP-55)

Floating labyrinth seal with additional dust flinger (IP-54)

Bearing end covers are also available.

Insulation

In order to prevent stray currents the ,MF Bearing can be supplied as an insulated version. The insulated bearing has a liner of synthetic insulating material on the spherical seat of the housing, which is particularly wear and temperature resistant. Alternatively, the bearing may be insulated below the bottom of the pedestal.

Heat Dissipation

The friction heat is normally dissipated by radiation and convection. When this is insufficient the bearing can be cooled by water cooler in oil sump of bearing or in other cases the oil supply with external oil cooling is available. Tapped holes for external oil supply are provided and connection for oil cooler can easily be machined.

Oil Selection

Depending upon the operating condition, normal branded mineral oil of suitable viscosity with low foaming tendency and good aging characteristics can be used. The exact viscosity grade of oil is available on request